An accelerometer is a smart sensor that measures how fast something speeds up, not counting gravity. It gives important info for lots of tech stuff we use every day. These gadgets are key for figuring out how things move and which way they’re facing in phones, cars, wearable tech, and machines. They turn movement into electric signals, helping cameras stay steady and airbags pop open at the right time. Accelerometers make gadgets easier to use, keep cars safe, and help scientists do their work. They’re super accurate and can do many things, making them a must-have in our world full of gadgets, moving things, and loads of data.

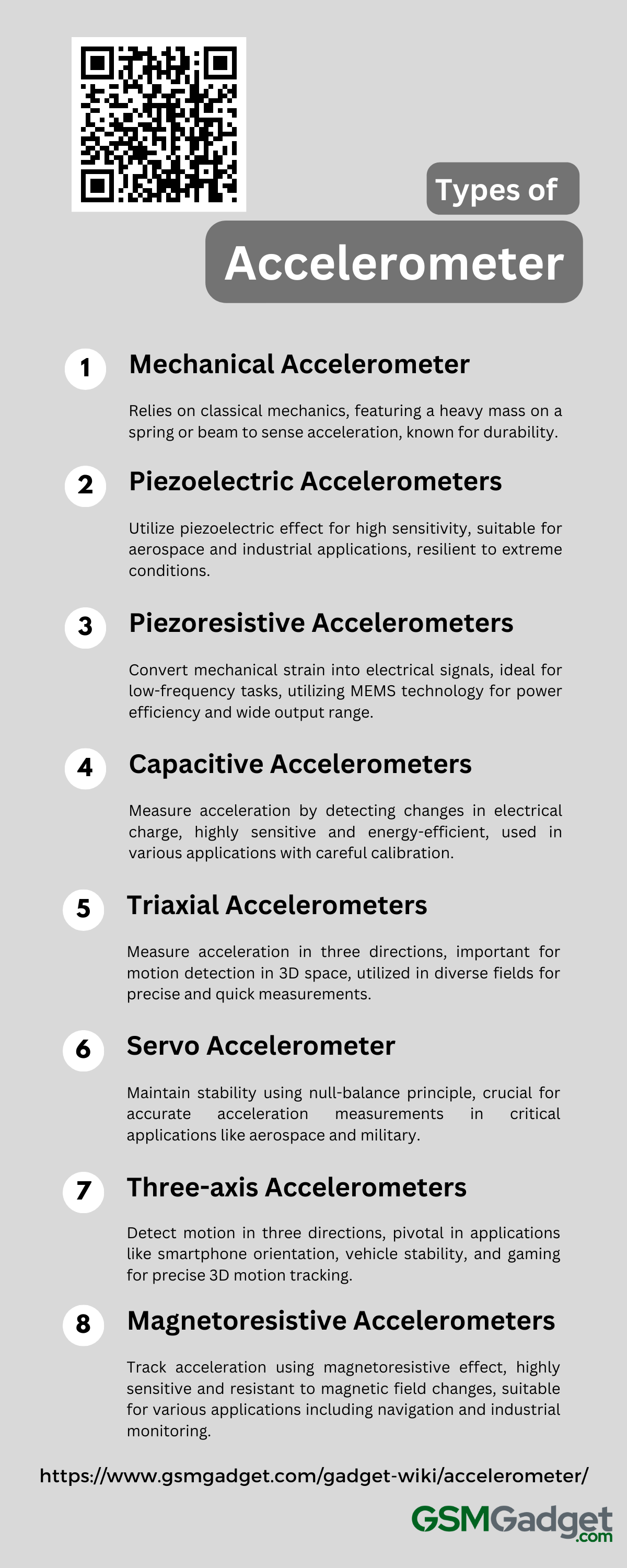

Types of Accelerometer

Accelerometers are key in today’s tech. They let devices sense and measure how fast they speed up. These sensors are crucial for lots of uses, like making mobiles better or helping spacecraft find their way. Let’s look at the six main kinds of accelerometers. Each one works differently and fits certain needs.

1. Mechanical accelerometer

Mechanical accelerometers are devices that measure how fast something speeds up. They work using the rules of classical mechanics and have a heavy mass attached to a spring or beam inside a frame. When they speed up, the mass moves, and this makes the mechanical part sense the change. This motion turns into an electric signal through methods like piezoelectric, capacitive, or strain gauge techniques. These accelerometers are known for being tough. They’re not as sensitive and react slower than electronic ones, but they’re super reliable in harsh conditions. That’s why they’re important in cars and planes. You can find simple, cheap ones for everyday gadgets or fancy ones for special science and industry jobs.

2. Piezoelectric Accelerometers

Piezoelectric accelerometers are known for their high sensitivity. They can measure acceleration, vibration, and shock very well over a broad range of frequencies. These devices work on the piezoelectric effect. This is when materials like quartz create an electric charge if they’re squeezed or pressed. The harder the press, the more charge they make. This feature lets these accelerometers be really accurate for all sorts of uses. People use them in aerospace tests, to check on industrial machines, in building projects, and even in gadgets we use every day. They’re built tough to handle extreme heat and cold, plus rough weather, all without needing outside power. But since they have high output impedance, they need special low-noise cables and amplifiers to make sure the data they collect is spot-on.

3. Piezoresistive Accelerometers

Piezoresistive accelerometers use the piezoresistive effect, where stress changes a material’s electrical resistance. These sensors turn mechanical strain into electrical signals to measure acceleration. Made mostly from silicon, they are sensitive and strong, perfect for low-frequency tasks like car crash tests, checking vibrations in machines, and in gadgets we use every day. They can pick up both still and moving acceleration, which is great for monitoring tilt, shakes, and sudden hits. While they can catch high-speed events and work at zero hertz for speed or distance measurements, they’re not as good with tiny vibrations and can be thrown off by temperature shifts. This means they need extra adjustments to give correct readings. These accelerometers are built using MEMS technology, making them power-saving. They offer a wide range of outputs and have special designs, like squeeze film damping, to handle resonant frequency issues. This makes sure they work well in all sorts of temperatures.

4. Capacitive Accelerometers

Capacitive accelerometers are sensors that measure how fast something speeds up. They do this by noticing changes in electrical charge. These changes happen when a weight inside moves because of acceleration, changing the space between two plates—one that doesn’t move and one that does. They’re known for being very sensitive and not using much power. Plus, they’re great at not picking up extra noise. These devices are used everywhere: in cars, planes, gadgets, and for checking on machines. They can tell both slow and quick movements, which is super useful for things like making sure cars stay steady and figuring out how you’re holding your phone. But to be really accurate, these sensors need to be set up just right and protected from stuff like temperature changes and unwanted electric signals.

5. Triaxial Accelerometers

Capacitive accelerometers are sensors that measure acceleration. They work by detecting changes in electrical charge when a mass inside shifts due to movement, altering the distance between two plates—one stationary and one movable. They’re highly sensitive and energy-efficient, plus they excel at reducing unwanted noise. You’ll find these devices in cars, planes, electronics, and for monitoring machinery. They can detect both slow and fast movements, which is handy for stabilizing vehicles and determining how you’re holding your phone. However, for top accuracy, these sensors must be calibrated carefully and shielded from things like temperature shifts and stray electrical signals.

6. Servo accelerometer

Servo accelerometers are known for their high precision and stability. They are key tools in measuring acceleration with accuracy. These devices work on a null-balance principle, using a feedback loop to keep a seismic mass stable inside. When acceleration moves the mass, a sensor detects this and sends a signal to a motor. This motor then applies a force to hold the mass steady. The amount of current used to balance the mass tells us the exact acceleration. These sensors come in two types: pendulous, with a pendulum as the inertial mass, and force-balanced, where a moving mass is kept in place by a counterforce. Because they’re so accurate, servo accelerometers are vital in critical jobs. They’re used in inertial navigation systems for aircraft, spacecraft, and submarines. They’re also important in the aerospace, military, and industrial fields for tracking motion and analyzing vibrations.

7. Three-axis accelerometer

Three-axis accelerometers are key sensors for motion detection. They measure acceleration in three directions: X, Y, and Z. They use tech like piezoresistive, capacitive, and MEMS (Micro-Electro-Mechanical Systems). These devices are important for knowing how something is oriented or moving in 3D space. They’re used in lots of ways, like turning smartphone screens, improving car stability, and making gaming and virtual reality more real. When picking one, you think about what you need it for. Things like how sensitive it is, its size, cost, accuracy, power use, and how tough it is matter a lot. They’re super important in fields like aerospace, cars, electronics, and health because they’re quick, precise, and small.

8. Magnetoresistive accelerometer

Magnetoresistive accelerometers are high-tech sensors that track acceleration. They work by using the magnetoresistive effect, where the resistance of materials changes with magnetic field shifts caused by movement. These devices are very sensitive and can pick up even small or slow movements. They can also tell when magnetic fields change because of nearby iron-based objects. These sensors are super useful in many areas, like keeping an eye on factory equipment, in cars, gadgets, for finding your way, and spotting vehicles. They’re small and tough, which means they’re great at detecting precise movements and staying accurate, even when things move fast or there’s a lot of metal around.

How does Accelerometers Work?

- Capacitive Sensing: Accelerometers use capacitive sensing. They sense when capacitance changes because a mass moves near a fixed plate. This movement turns into an electrical signal.

- Mass-Spring System: They have a weight attached to a spring that moves when there’s acceleration. How much it moves shows how much inertia there is.

- Piezoelectric Effect: Some models use the piezoelectric effect to create electricity. This happens when a material that can generate an electric charge is squeezed by the movement of mass during speeding up.

- Signal Processing: The electrical signal from the accelerometer, whether it’s analog or digital, gets cleaned up and processed. This way, we can figure out the exact amount of acceleration.

- Axis Measurement and MEMS Technology: MEMS accelerometers are tiny sensors in many gadgets. They figure out which way is up and how fast things move by checking acceleration in different directions. They’re popular because they’re small, don’t cost much, and use tech that feels changes in pressure or electric fields.

Applications of Accelerometers

Accelerometers are pivotal components in modern technology, serving as the backbone for motion detection across various industries. From enhancing personal device functionality to advancing aerospace navigation, these sensors provide critical data by measuring acceleration forces. Here are some key applications where accelerometers make a significant impact:

1. Smartphones, tablets and digital cameras

Accelerometers are critical in advancing the functionality and enhancing the user experience across smartphones, tablets, and digital cameras. These sensors are key to automatic screen orientation adjustments, enabling a fluid switch between portrait and landscape views, and they bolster motion-based commands for interactive gaming and fitness apps. Their role extends to step tracking and enabling ‘tap-to-wake’ features in mobile devices. In the realm of digital photography, accelerometers contribute to image stabilization by counteracting hand tremors, ensuring photographs are crisp and clear. They also ascertain the camera’s orientation to tag photos with accurate metadata, guaranteeing images are displayed correctly across various devices. By significantly improving interactivity and performance, accelerometers are indispensable in these ubiquitous electronic gadgets.

2. Automotive industry

In the automotive industry, accelerometers are vital for various safety and performance features, significantly enhancing vehicle safety, performance, and comfort. These sensors are key in airbag systems, detecting sudden deceleration to trigger inflation and protect passengers during collisions. They also underpin Electronic Stability Control (ESC) and Anti-lock Braking Systems (ABS), where they monitor vehicle motion and orientation to prevent skids and wheel lockup, respectively, aiding in maintaining control during critical situations. Beyond safety, accelerometers inform active suspension systems for a smoother ride and are used in telematics to monitor driver behavior, vehicle dynamics, and support predictive maintenance. As vehicles evolve towards autonomy, accelerometers are increasingly crucial in driver assistance technologies, playing an expansive role in ensuring passenger safety and comfort.

3. Aerospace and aviation

In the aerospace and aviation sectors, accelerometers are indispensable for ensuring both performance and safety. These advanced sensors are key to navigation and control systems, measuring acceleration to provide vital data on an aircraft’s or spacecraft’s position, velocity, and orientation. They are essential to inertial navigation systems in commercial aviation, guiding aircraft when GPS is unavailable, and play a crucial role in passenger safety by triggering airbag deployment during crashes. In space exploration, accelerometers facilitate satellite dish orientation and spacecraft stabilization. Additionally, they monitor aircraft stability, detect engine vibrations to prevent in-flight failures, and contribute to structural health monitoring by tracking stress and fatigue. Flight testing also relies on accelerometers to confirm that aircraft meet design and safety benchmarks. With the advent of MEMS-based accelerometers, the industry benefits from devices that offer enhanced sensitivity and accuracy, even in challenging environments, ensuring informed decision-making and optimal flight performance.

4. Drones

In the technological ecosystem of modern drones, accelerometers are essential for ensuring stable flight and precise maneuvering. These sensors accurately measure linear acceleration and tilt angles, providing vital data for flight control systems to maintain the drone’s orientation and stability, even in the face of external forces such as wind. This capability is critical for a variety of applications, from aerial photography, which demands steady hovering, to surveying landscapes where precise positional information is paramount. Moreover, accelerometers facilitate advanced functionalities like collision avoidance and the execution of autonomous flight paths, thereby enhancing both the performance and safety of unmanned aerial vehicles (UAVs) by enabling more controlled, agile navigation and smoother landings.

5. Rotating machinery

In industrial and mechanical engineering, accelerometers are essential for monitoring the health of rotating machinery such as turbines, engines, pumps, and fans. These devices detect vibrations and motion, providing key insights into equipment performance and potential issues. Triaxial accelerometers, which measure acceleration in three dimensions, are particularly valuable for identifying the specific nature of vibrations, enhancing fault diagnosis in complex systems. The data from accelerometers supports predictive maintenance, enabling timely interventions to prevent downtime and extend machinery lifespan by identifying misalignments and wear in components. Their ability to handle a wide range of signal amplitudes makes them versatile tools for ensuring machinery operates at peak efficiency, contributing to proactive machinery management and safety.

6. Structural monitoring and geophysics

In the combined fields of structural monitoring and geophysics, accelerometers are indispensable tools that provide essential data for evaluating the dynamic behaviors of structures and the Earth’s movements. Utilized in structural health monitoring, these devices detect subtle vibrations within constructions such as buildings and bridges, aiding engineers in identifying potential defects and averting structural failures, thereby ensuring safety and prolonging infrastructure lifespan. In seismology, a branch of geophysics, accelerometers measure ground motions during seismic events, contributing to earthquake epicenter localization and the advancement of early warning systems that bolster community preparedness and reduce disaster impact. The insights gained from accelerometer data are critical for enhancing the resilience of structures and deepening our comprehension of geological phenomena, ultimately leading to improved strategies for disaster readiness and infrastructure preservation.

7. Health and fitness

Accelerometers have revolutionized health and fitness by enabling precise monitoring of physical activity through wearable technology such as fitness trackers, smartwatches, and smartphones. These sensors offer objective measurements of motion, translating a user’s movement into digital data that tracks steps, calories burned, sleep patterns, and fall detection. This information not only aids individuals in achieving their fitness goals but also assists healthcare professionals in patient monitoring, rehabilitation, and chronic disease management. In sports medicine, accelerometers analyze athletes’ performance, informing tailored training programs. While challenges in data accuracy and device placement affect health assessments, advancements in accelerometer technology continue to promote active lifestyles by informing interventions to decrease sedentary behavior.

How to select an accelerometer?

When selecting an accelerometer, consider the following factors:

- Measurement Range: Identify the maximum acceleration levels you need to measure, typically noted in ‘g’ units, to ensure the device can handle the expected range of motion.

- Frequency Response: Choose an accelerometer that can accurately capture vibrations within the specific frequency range relevant to your application, which is crucial for precise measurements.

- Sensitivity: Opt for an accelerometer with the appropriate sensitivity, often expressed in mV/g, to detect both high and low-level accelerations as required by your use case.

- Temperature Range: Verify that the accelerometer can perform reliably within the environmental temperature extremes it will encounter during operation.

- Mounting and Output Type: Decide on a suitable mounting method, such as adhesive or stud, that fits the application’s physical context, and select the correct output type (analog or digital) that is compatible with your data acquisition system.

Benefits and uses of Accelerometer

Accelerometers are key sensors in today’s tech, measuring how fast an object speeds up or slows down. They’re used in many areas, like making smartphones smarter and car safety better. Here are some main perks of using accelerometers:

1. Motion Sensing

Accelerometers are key to modern tech, acting as the core for motion sensing in many devices. These sensors pick up both still and moving forces, which lets them do a lot of things in different areas. In gadgets like phones and fitness trackers, they’re crucial for flipping the screen, counting steps, and checking health stats. This makes using devices better and helps people stay fit. Car makers use accelerometers for safety stuff, like keeping cars stable and setting off airbags when there’s a quick stop, making rides safer. Also, in gaming and virtual reality, these sensors help make super cool experiences by making sure the game follows your moves well. The fact that accelerometers are everywhere shows how important they are for interactive, easy-to-use, and safe tech.

2. Orientation Detection

Accelerometers play a huge role in today’s tech, making it easy for gadgets to figure out which way is up. This makes our devices smarter and more user-friendly. For example, they help your phone or tablet screen flip to the right way when you turn it. In video games, they let you move things around by just tilting your controller, adding fun to the game. Cars use them too; they keep an eye on how the car tilts and turns, so safety stuff can kick in if needed. Health trackers and smartwatches also use accelerometers to watch how you move, helping with fitness goals and health checks. Plus, they’re super important for keeping us safe, like in navigation tools and gadgets that detect if someone falls. In short, accelerometers are key for cool and smooth interactions with all kinds of tech.

3. Activity Monitoring

Accelerometers are key for tracking activities. They’re in many devices, like phones and fitness bands, and are extremely important for health apps. They can detect even the tiniest motions. This means they can tell how many steps you take, how intense your workouts are, and if you’re sleeping well. They convert all that movement into useful information. This helps provide instant feedback to users, encouraging them to make better health choices. It’s also very important for doctors and sports experts who need to monitor how patients or athletes move. The information from accelerometers helps create personalized workout plans, check if a treatment is working, and improve training strategies. Plus, they don’t use much power and operate quietly, making them perfect for monitoring your activity all the time.

4. Vehicle Dynamics

Accelerometers are crucial for how cars work. They give important info on how fast a car speeds up and its tilt, making driving safer and better. These gadgets are a big part of Electronic Stability Control (ESC) and Traction Control Systems (TCS). They stop cars from skidding and losing grip on the road. In fast cars, they tweak how the suspension works to help with handling and control the car’s frame better. These sensors are super important when testing if airbags work right, setting them off when they sense a sudden stop. They also help figure out what happened in a crash by recording data before the crash occurs. With accelerometers in cars, drivers get a smoother ride with more control, feeling more confident and comfy thanks to better stability and performance checks.

5. Industrial Applications

Accelerometers are key in many industries. They help keep machines healthy and efficient by checking vibrations and predicting when maintenance is needed. These sensors can handle both high and low-frequency vibrations. They’re often attached to important parts like bearings and gearboxes to spot problems early and prevent costly shutdowns. These sensors are also important in aerospace to keep aircraft stable, in cars to improve how they drive and stay safe, and in construction to check if structures are solid. Accelerometers are tough and can work in extreme conditions, which makes them essential for safety and automated systems in tough industrial settings. The rise of MEMS technology has changed how we monitor conditions. It gives us affordable, scalable, and energy-saving accelerometer options. These advancements help operations run better and last longer in different fields.

6. Navigation Systems

Accelerometers are key to making modern navigation systems more accurate and reliable, especially in Inertial Navigation Systems (INS). These sensors track linear acceleration in different directions. This is crucial for knowing how something moves and where it points, even when GPS signals are weak, like in tunnels or busy city areas. They give important info on how fast and in what direction something is moving. This helps figure out speed and position, so we can keep tabs on location all the time. When used with gyroscopes and magnetometers in an Inertial Measurement Unit (IMU), accelerometers help fix any drifts or mistakes. This feature is super important for directing vehicles and planes. It’s also handy for personal navigation on smartphones, making sure people get where they’re going smoothly and safely.

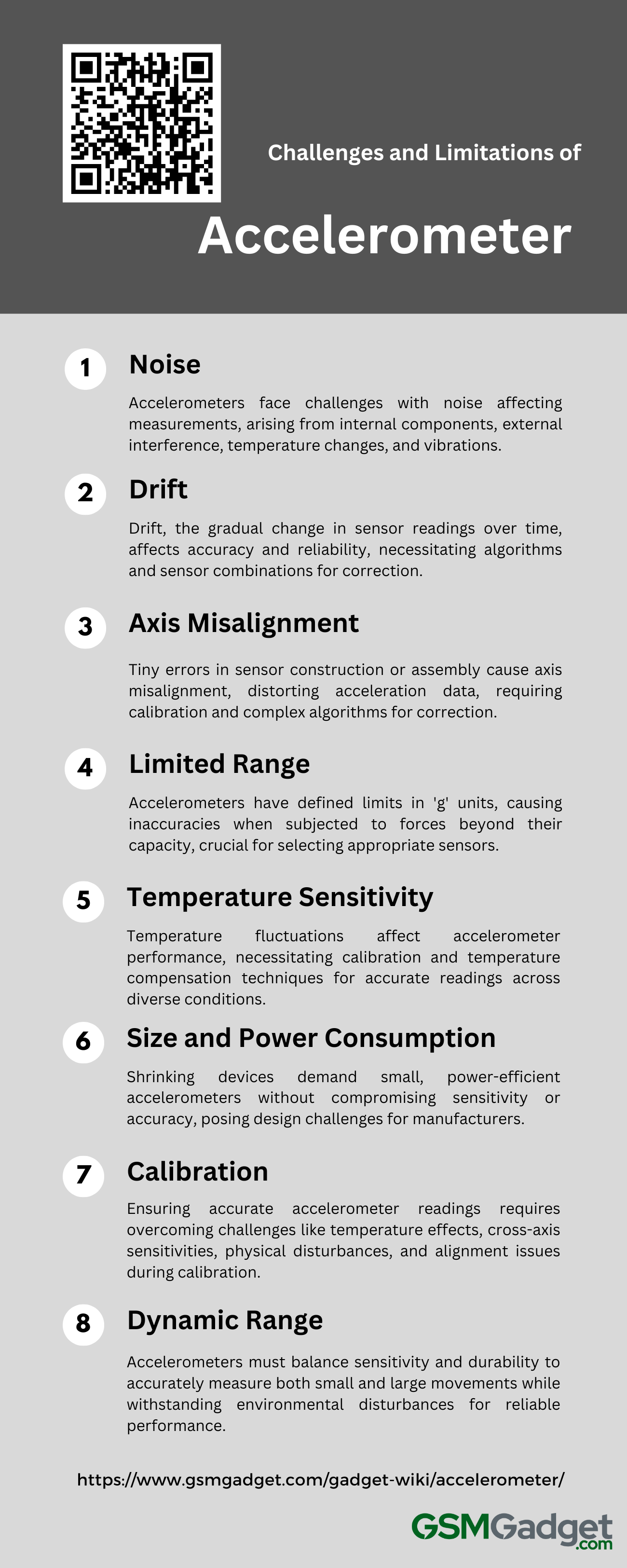

Challenges and Limitations of Accelerometer

Accelerometers are key for tracking speed changes in devices, but they run into a few problems. They can have trouble with calibration, react to things like temperature and humidity, and must be set up just right in systems to work well.

1. Noise

Accelerometers are key in motion sensing for many uses. But they struggle with noise that can mess up measurements. This noise comes from things like the device’s own parts, outside electrical interference, temperature changes, and shakes. It can make readings wrong in gadgets and navigation systems. Using filters can help, but might remove important parts of the signal. The big task is to reduce noise without losing signal quality. This needs smart software and careful setup to keep accelerometer readings reliable and accurate. Problems like noise from electrical or magnetic sources need special fixes like using shielded wires and placing things carefully. Also, piezoelectric accelerometers can be sensitive to wire noise, so they need special wires and firm installation. For applications that need to be very sensitive, having a low level of background noise is super important. Despite these challenges, new tech and ways to handle noise are making accelerometer data better.

2. Drift

Accelerometers are key in measuring how fast things speed up in motion-sensing tech. But they have a problem called drift. This is when the sensor’s readings change on their own over time, even if there’s no real movement. Drift can mess up how we figure out speed or where something is, which is a big deal for navigation systems that need to be super accurate. Drift happens because of things like sensor noise, changes in temperature, stress on the parts, getting old, and issues from when they were made. To fix this, experts use smart algorithms and combine data from different sensors, like gyroscopes and magnetometers. This helps correct the accelerometer’s mistakes and makes the data more trustworthy and exact. People are always working on new ways to make these fixes better. They’re trying to reduce drift as much as possible so devices that depend on accelerometer info can perform their best.

3. Axis Misalignment

Accelerometers are key for tracking movement and direction in many devices, from smartphones to spacecraft. They often face a challenge called axis misalignment. This means the sensor’s axes don’t line up perfectly with the target frame because of tiny errors in making or putting them together, or changes when they’re used. Misalignment can twist the data, leading to wrong acceleration readings and mistakes where movement seems to happen on the wrong axis. To fix this, engineers use special calibration and complex algorithms. Even though high-end accelerometers come pre-calibrated, everyday gadgets might need tough calibration steps that don’t always solve the problem completely. Sometimes the error can be over 1°. This shows we need better accelerometer tech and sharper ways to calibrate to get the accuracy needed for precise tasks.

4. Limited Range

Accelerometers are key for measuring how fast something speeds up in different uses. They have a set limit, called ‘g’ units, that can cause problems. If the sensor faces forces too strong for it, it might not give correct readings. This is especially important when dealing with heavy machinery, space stuff, or electronics that move suddenly. High sensitivity accelerometers are great for small movements but can have trouble with very fast or big ones. This can mess up the signal. So, it’s super important to pick and set up an accelerometer that fits what you expect it to handle. Doing this helps avoid wrong data and keeps equipment from breaking down. You need to make sure the sensor’s range matches what the job needs.

5. Temperature Sensitivity

Accelerometers are key for measuring how fast things speed up in gadgets like phones and spaceships. But they have a big problem: they’re sensitive to temperature changes. These shifts can mess with the sensor’s parts, making them less stiff or changing how they move. They can also affect how the sensor measures motion, leading to wrong data. This gets even trickier when temperatures are really high or low, or keep changing quickly. To deal with this, companies use special ways to keep readings accurate. They calibrate the sensors carefully and sometimes add extra temperature sensors that make adjustments on the fly. Still, it’s tough to keep things precise in all kinds of weather. That’s why it’s super important to think about the environment when looking at the data. And why experts keep trying to make accelerometers that handle temperature changes better.

6. Size and Power Consumption

Accelerometers are key in motion sensing tech but they face issues with getting smaller and using less power. As devices like smartphones and wearables shrink, we need tiny accelerometers that still work well. But making them small can make them less sensitive and accurate. They also need to use little power, especially for gadgets that run on batteries and need to last a long time. Designers have to balance low power use with keeping good performance. For example, the BMA400 accelerometer is designed to use very little power. However, saving power can sometimes affect how precise the measurements are and increase noise. So, manufacturers keep working hard to make accelerometers both small and power-efficient while ensuring they stay reliable for different uses.

7. Calibration

Calibrating accelerometers is key for getting correct and dependable readings. However, it’s not easy due to several issues. Changes in temperature can mess with the readings and mean you have to recalibrate often to keep things accurate. The tools we use to calibrate, along with the sensor’s own noise and uneven outputs, limit how precise we can get. There’s also the problem of cross-axis sensitivities. This means we need to calibrate each axis separately, which requires complex math and special care. Physical bumps and knocks can cause errors in tilt measurements too. And if the calibration device isn’t lined up right, that can make the readings less accurate as well. Even with these challenges, we’re making progress in how we calibrate, making accelerometer data more precise and reliable. But it still takes a lot of time and technical know-how.

8. Dynamic Range

Accelerometers are key in many tech areas, from smartphones to space. They face issues with their dynamic range—that’s how much movement they can measure accurately. If the range is too limited, an accelerometer might not catch both tiny and huge movements, like a building shaking or an earthquake hitting. It needs to be sensitive but also tough enough to not get damaged. Things like temperature and other disturbances can mess up the dynamic range and how well the sensor works. The kind of technology used in the accelerometer, like capacitive, piezoelectric, or MEMS, affects its range and balance between being sensitive, responding to different speeds, and working within certain limits. Picking and setting up the right accelerometer for a job is super important. It makes sure it can deal with the expected movements without problems.